The standard test for when it’s safe to strike formwork for poured concrete structures is the cube crush method. But we know that the curing rate and physical properties of test cubes at a given point of time will not be identical to the poured structure.

Size and shape make a significant difference to the internal temperature and the curing rate. The temperature at the core of a large, poured concrete structure is likely to be higher than at the centre of a test cube due to the thicker concrete retaining more heat from the exothermic curing reaction. This will accelerate the cure.

In other words, if you understand what’s really happening in the core of the poured concrete it could be safe to remove (or strike) the supporting formwork sooner than indicated by the cube crush tests. Follow-on project activities can then start sooner to speed up overall delivery.

Testing the Theory

Octavius put this theory to the test on the HS2 and Chelmsford Schemes. Monitoring the concrete core was achieved by casting sacrificial thermocouple wires into the concrete. These were attached to transmitters secured on the formwork outside of the concrete which linked to an online portal, giving real-time data on the internal temperature and curing rate.

Initially, data from the monitors was compared to the cubes taken and tested using the traditional cube crush method. Once confidence was established in the test results, the monitoring method was adopted in several instances as the primary method of evaluating when it was safe to strike.

Time Savings

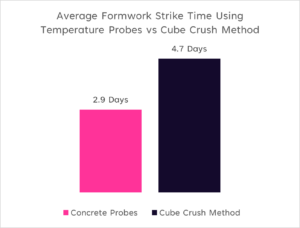

Depending on various factors, it was possible to remove formwork up to five days sooner than would have been the case with cube crush tests. One factor, the delay in waiting for lab test availability and results, was eliminated entirely.

Excluding initial investment in transmitter boxes, the estimated cost of using the monitoring method is approximately £20 per pour, compared to £250 for a set of three cubes. To create a reliable and representative set of results, multiple probes were used for each pour. For small pours up to 20m3, three probes were found to be adequate. Four were needed for pours up to 150m3 and six or more for larger structures.

Quality Control

Monitoring the conditions at the core of a poured concrete structure has additional benefits. These include knowing when concrete temperatures have deviated from the allowable range dictated by the specification. This can have a major impact on the physical properties of the cured concrete.

Which goes to prove that watching concrete set can be more interesting than most people imagine if you have an inquisitive mindset and a thirst for innovation.

If you’d like further information about Octavius project work, please contact: hello@octavius.co.uk